In the ever-evolving world of custom apparel, understanding the differences between DTF vs. DGT printing methods can significantly impact your production quality and efficiency. Both Direct to Film (DTF) and Direct to Garment (DGT) have emerged as popular choices among businesses looking to elevate their custom apparel printing. While DTF printing benefits from its versatility across numerous fabric types, DGT printing details highlight its capacity to produce intricately detailed designs with a rich color palette. This guide will delve into the nuances of comparing DTF and DGT, ensuring you have the insights needed to choose the best printing methods for garments tailored to your specific needs. With the right knowledge, you can confidently enhance your custom apparel printing processes and meet the demands of your clientele.

When it comes to the realm of textile printing for custom garments, the debate often centers around Direct to Film (DTF) versus Direct to Garment (DGT) techniques. These innovative printing solutions have revolutionized the way designs are applied to fabrics, with each offering unique benefits suited to different business requirements. Understanding how DTF and DGT printing work is crucial for making educated decisions that align with your creative visions and market needs. This comparison will not only illuminate the various aspects of these printing technologies but will also serve as a crucial resource for businesses striving to optimize their printing methods for garments. Whether you are a startup or an established brand, comprehending these two approaches can help you streamline your custom apparel printing endeavors.

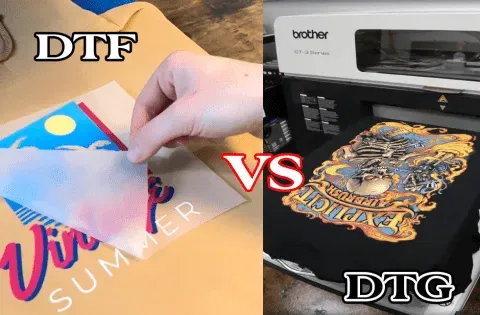

Comparing DTF and DGT: Key Differences in Printing Methods

When evaluating DTF versus DGT, it’s essential to recognize the fundamental differences in their printing processes. DTF, or Direct to Film printing, involves the initial creation of a film that captures the design. This film is heated and transferred onto the garment, making it a versatile option for various fabric types, including cotton and polyester. On the other hand, DGT, or Direct to Garment printing, applies ink directly onto the fabric using specialized inkjet technology. This direct application allows for intricate designs and high-resolution prints, establishing DGT as a go-to choice for detailed graphical representations.

Another critical difference lies in the production process efficiency. DTF printing is generally considered more favorable for low-volume runs. Its setup costs are comparatively lower, making it accessible for startups and small businesses. In contrast, DGT is better suited for larger quantities of garments where detailed designs are a priority. The operational efficiency in high-volume production can translate to lower per-unit costs, making it ideal for established brands with consistent design requirements.

Benefits of DTF Printing for Custom Apparel

DTF printing offers numerous benefits, particularly for businesses in the custom apparel space looking for flexibility and cost-effectiveness. One of the standout advantages of this method is its ability to print on a wide array of fabric types. Whether you’re working with cotton, polyester, or blends, DTF can efficiently produce eye-catching designs on diverse textiles. This flexibility ensures that businesses can cater to varied customer preferences without investing in multiple printing methods.

Durability is another crucial benefit of DTF prints. The finished product typically withstands multiple washes without fading, making it a reliable choice for garments meant to last. This durability is vital for businesses that prioritize quality, as it ensures customer satisfaction and repeat purchases. Additionally, DTF is often less expensive for smaller production runs, making it a strategic option for brands introducing new designs or testing market trends.

Exploring DGT Printing: Advantages and Applications

DGT printing shines in applications that demand high detail and color vibrancy. This method utilizes advanced inkjet technology to deliver intricate designs with exceptional clarity. It is especially beneficial for custom apparel that features complex images or gradients, as it can reproduce colors more accurately than many other printing methods. Brands looking to produce elaborate graphics or personalized items can leverage DGT’s capabilities to stand out in a competitive market.

Another advantage of DGT printing is its eco-friendliness. Many modern DGT inks are water-based, which aligns with the growing demand for sustainable practices within the fashion industry. With environmentally conscious consumers seeking out products that minimize their ecological footprint, incorporating eco-friendly DGT printing can enhance your brand’s appeal. As businesses increasingly focus on sustainability, DGT offers a pathway to meet both aesthetic and environmental demands.

Key Considerations for Choosing Between DTF and DGT

Deciding between DTF and DGT printing requires careful consideration of several factors tailored to your specific business needs. One primary aspect is production volume; DTF tends to be more suitable for low-volume projects due to its lower setup costs, which is beneficial for brands just starting out or exploring new designs. Conversely, if your operation involves mass production with a consistent design, DGT may present advantages in speed and efficiency that are critical for meeting consumer demand.

Additionally, the complexity of your designs plays a significant role in this decision. If your custom apparel features intricate patterns or requires detailed artwork, DGT undoubtedly holds an edge in its capacity to capture fine details and gradients. However, if versatility and cost-effectiveness are your goals, especially for a diverse range of fabric types, DTF may be the method that best addresses your operational dynamics.

Recent Trends in DTF and DGT Technology

Recent advancements in DTF technology are primarily focused on enhancing the speed and quality of production. Newer printing machines are being introduced that reduce the time required to print films while improving the quality of ink application. Innovations in ink formulations, coupled with advancements in printer capabilities, ensure that businesses can meet high-quality standards while optimizing production costs. As the demand for custom printing continues to rise, these developments are crucial for keeping pace with consumer expectations.

Similarly, DGT technology is also evolving rapidly, with manufacturers focusing on creating faster, more efficient printers that can handle higher volumes without sacrificing quality. Many companies are now offering eco-friendly inks designed to reduce environmental impact. This shift not only supports sustainable business practices but also appeals to a growing demographic of consumers who prioritize eco-consumption. Both DTF and DGT are adapting to the digital era, positioning themselves to meet the evolving needs of the custom apparel market.

Understanding the Market Demand for Custom Apparel Printing

As consumer preferences continue to evolve, the demand for custom apparel printing is on the rise. Businesses are increasingly looking for methods that allow them to create unique, personalized pieces that resonate with their customer base. This trend is particularly evident in the rise of limited edition designs and small batch productions, where both DTF and DGT can effectively cater to specialized niches within the market. As brands strive to differentiate themselves, the ability to offer customized and high-quality products will become more pertinent.

Moreover, the potential for e-commerce growth in the custom apparel sector cannot be understated. Direct-to-consumer models are flourishing, enabling brands to engage with consumers directly and prompt rapid design iterations based on real-time feedback. This dynamic creates an opportunity for both DTF and DGT printers to offer flexible solutions that adapt to shifting consumer demands while maintaining quality and efficiency. As trends in apparel demand continue to change, implementing the right printing technology will be a decisive factor for success.

Frequently Asked Questions

What are the main benefits of DTF printing compared to DGT?

DTF printing offers several benefits over DGT, including versatility across various fabric types, greater durability with prints that resist fading after multiple washes, and cost-effectiveness for low-volume production runs. These attributes make DTF a popular choice among businesses looking to balance quality and budget.

How does DGT printing excel in design intricacy when comparing DTF vs. DGT?

DGT printing shines in producing intricate designs with high detail, surpassing DTF in this aspect. Its inkjet technology allows for superior color gradients and fine detail resolution, making it ideal for complex artwork and high-resolution designs in custom apparel.

Which printing method is more cost-effective for small businesses: DTF or DGT?

DTF printing is generally more cost-effective for small businesses or startups engaging in lower production volumes. The initial setup costs are typically lower compared to DGT, allowing businesses to explore a variety of designs without significant financial commitment.

What fabric types are best suited for DTF vs. DGT printing methods?

DTF printing is versatile and works well on numerous fabric types, including cotton and polyester. In contrast, DGT printing may require specific fabric compositions for optimal results, often performing best on 100% cotton or cotton-blend materials.

Can DGT printing be considered eco-friendly when comparing it to DTF printing?

Yes, many modern DGT inks are water-based and more environmentally friendly than traditional solvent-based inks. This eco-friendly composition appeals to environmentally conscious consumers and sets DGT apart in terms of sustainability when compared to DTF printing methods.

What should businesses consider when choosing between DTF and DGT for custom apparel printing?

When comparing DTF vs. DGT, businesses should consider factors such as the volume of production, design complexity, suitable fabric types, and budget constraints. Analyzing these aspects ensures that the selected printing method aligns with operational needs and artistic goals.

| Feature | DTF (Direct to Film) | DGT (Direct to Garment) |

|---|---|---|

| What It Is | Printing onto a film, then transferring to fabric | Directly applying ink onto fabric using inkjet technology |

| Fabric Compatibility | Cotton, polyester, and more | Best suited for certain fabric compositions |

| Durability | Long-lasting; resists fading after washing | Varies; depends on fabric and ink used |

| Cost Effectiveness | More cost-effective for low-volume runs | Higher initial setup costs; efficient for large runs |

| Design Complexity | Versatile, but less detailed than DGT | Superior detail suitable for intricate designs |

| Eco-Friendliness | Depends on inks used (may vary) | Often uses eco-friendly water-based inks |

Summary

DTF vs. DGT printing methods have distinct advantages and are suited for different production needs. DTF offers remarkable versatility, allowing businesses to print on various fabrics while being cost-effective for smaller runs. On the other hand, DGT shines in producing high-quality, detailed designs on selected fabrics and is favored for richer color variety. Ultimately, the decision should align with your production volume, design complexity, and budget considerations. Understanding these differences is essential for optimizing your custom apparel production.