DTF transfers, or Direct-to-Film transfers, represent an exciting advancement in the realm of T-shirt printing, offering a new avenue for custom apparel enthusiasts and business owners alike. This innovative DTF technology allows for the transfer of vibrant, detailed designs onto various fabric types, ensuring high-quality results that traditional methods often fail to achieve. With its ability to work across diverse materials and produce intricate artworks, DTF printing has quickly gained traction in the competitive landscape of apparel decoration. As the demand for personalized clothing increases, understanding DTF transfers will open doors to a world of creative possibilities tailored to individual style preferences. In this guide, we’ll dive deep into the benefits of DTF transfers and explore how they are shaping the future of custom T-shirt printing.

When discussing modern printing techniques for textiles, you may come across terms such as Direct-to-Film (DTF) printing, a method that is rapidly reshaping the custom apparel market. This technology stands out due to its ability to create high-quality prints with vivid colors and intricate details that appeal to today’s fashion-forward consumers. As the popularity of personalized clothing surges, alternative phrases like custom apparel solutions and digital T-shirt printing have come into play, pointing to the shift towards more bespoke options in the industry. Whether you’re involved in creating unique designs for a small business or seeking to make a fashion statement, understanding these terms and the underlying technology is crucial. In the upcoming sections, we will delve further into the features and advantages of DTF and its implications for the future of textile printing.

Understanding DTF Transfers for T-Shirt Printing

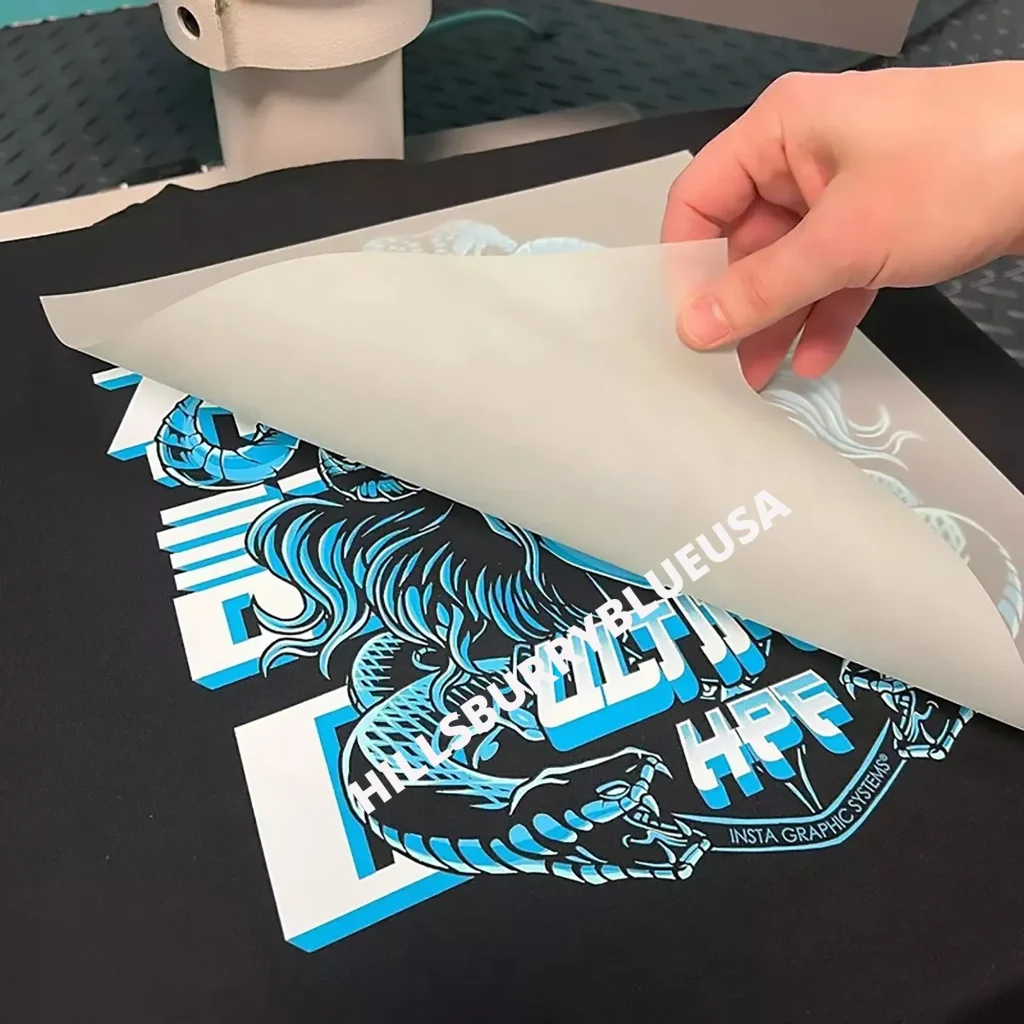

DTF transfers, or Direct-to-Film transfers, represent a significant leap forward in the world of T-shirt printing. This innovative method allows images to be printed onto a specialized film, which is then heat-activated to bond with various fabric types. The process is remarkably versatile, catering to an array of materials, from cotton to polyester blends, making DTF printing an excellent choice for custom apparel manufacturers seeking flexibility in their designs.

The appeal of DTF transfers lies not only in their quality but also in their ability to reproduce intricate artwork with stunning detail. Unlike traditional methods like screen printing, which often struggle with complex visuals or color blending, DTF technology excels in delivering high-resolution graphics. The result is eye-catching apparel that attracts attention, perfect for both small businesses and individual creators looking to make a unique statement.

The Benefits of DTF Technology for Custom Apparel

DTF technology is gaining traction thanks to its numerous advantages in the custom apparel space. One prominent benefit is its cost-effectiveness, particularly for small to medium-sized businesses. DTF printing generally incurs lower initial setup costs compared to traditional printing methods. Additionally, since there is no minimum order requirement, businesses can efficiently manage inventory by producing items on-demand, reducing waste and maximizing profit margins.

Moreover, the ease of use associated with DTF transfers empowers entrepreneurs and hobbyists alike to venture into T-shirt printing. The process involves straightforward steps: design creation using graphic software, printing onto the film, and using a heat press for application. This user-friendly approach allows anyone to start creating their own custom apparel with minimal technical expertise, paving the way for more innovative designs and broader market opportunities.

Environmental Advantages of DTF Transfers

In an era where sustainability is paramount, DTF transfers stand out as a more environmentally friendly option for apparel printing. Featuring water-based inks, DTF technology reduces the reliance on harmful solvents commonly used in other printing processes. As consumers become increasingly concerned about environmental issues, opting for eco-friendly printing methods like DTF can serve as a significant selling point for brands dedicated to sustainable practices.

Furthermore, DTF’s ability to operate with less wasteful practices makes it an attractive alternative in the apparel industry. By embracing on-demand production, custom apparel businesses can meet consumer demands without over-producing, thus minimizing environmental impact. This approach not only helps address waste management challenges but also aligns with the growing movement towards ethical consumerism.

Recent Innovations in DTF Printing Technology

The landscape of DTF printing continues to evolve, with ongoing innovations aimed at enhancing the efficiency and quality of prints. Recent advancements include the development of superior ink formulations that significantly improve wash resistance and durability, ensuring that vibrant designs withstand the test of time and maintain their aesthetic appeal even after multiple washes. Such improvements directly benefit the consumer experience, making DTF transfers a reliable choice for high-quality apparel.

Additionally, enhanced production speeds are revolutionizing the DTF printing process. Innovations are allowing businesses to fulfill larger orders more swiftly, adapting to the surge in demand for custom apparel. This increase in efficiency not only supports larger-scale production runs but also attracts clients who need quick turnaround times, further establishing DTF technology as a leading choice in the market.

Market Trends Impacting DTF Transfers

As we move into a new era for the apparel industry, market trends indicate a rapid shift towards customization and personalization. DTF transfers are at the forefront of this movement, resonating with consumers’ desire for unique clothing options that reflect their individual styles. The rise of e-commerce platforms specializing in custom apparel is bolstering interest in DTF printing, making it easier for consumers to access personalized fashion solutions.

Analysts predict that the popularity of DTF transfers will continue to grow, further solidifying the technique’s place in the T-shirt printing industry. This trend is driven by the simultaneous increase in consumer interest in sustainability and the desire for bespoke designs. As more businesses integrate DTF technology into their production processes, we can anticipate a significant evolution in how fashion is consumed and marketed.

Getting Started with DTF Transfers: A Beginner’s Guide

For those interested in diving into the world of DTF transfers, the initial steps are simple yet crucial. First, investing in quality equipment, such as a reliable DTF printer and a heat press, is essential for achieving the best results. Researching reputable brands will ensure you choose equipment that meets your printing needs and maintains quality standards, setting the foundation for successful T-shirt printing.

Next, familiarity with graphic design software is another important step. This knowledge allows you to create stunning visuals that can be effectively translated onto T-shirts using DTF printing methods. Finally, experimenting with different designs and fabrics will not only enhance your skills but also help you develop a distinctive product line that resonates with your target audience, ensuring a competitive edge in the ever-evolving custom apparel market.

Frequently Asked Questions

What is DTF printing and how does it work in T-shirt printing?

DTF printing, or Direct-to-Film printing, is a method where designs are printed onto a special film and then transferred onto fabric using a heat press. This technique provides high-resolution images, vibrant colors, and is suitable for various materials, making it a popular choice in custom apparel.

What are the advantages of using DTF transfers over traditional T-shirt printing methods?

DTF transfers offer several advantages over traditional methods like screen printing, including superior quality with intricate designs, versatility across multiple fabric types, cost-effectiveness due to lower setup costs, and a user-friendly process ideal for beginners.

Can DTF technology be used on different types of fabrics for custom apparel?

Yes, DTF technology is highly versatile and can be used on various types of fabrics, including cotton, polyester, and blends. This flexibility allows for unique and customized designs across a wide range of apparel options.

How cost-effective is DTF printing for small businesses in the custom apparel industry?

DTF printing is particularly cost-effective for small businesses because it has lower setup costs and does not require minimum order quantities. This makes it ideal for on-demand printing and targeting niche markets with personalized products.

What environmental benefits are associated with DTF transfers in the T-shirt printing process?

DTF transfers use water-based inks, which are less harmful to the environment compared to traditional solvent-based inks. This eco-friendly approach aligns with the increasing demand for sustainable fashion and can attract environmentally conscious consumers.

What equipment do I need to get started with DTF transfers for T-shirt printing?

To start with DTF transfers, you need a DTF printer, heat press, and quality DTF inks and films. Additionally, familiarity with graphic design software will help you create appealing designs ready for printing.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | DTF transfers involve printing designs onto a special film that is then transferred onto fabric with heat. This method provides high-resolution images and vibrant colors. |

| Quality and Detail | DTF prints offer intricate designs and challenging effects like blends and gradients, making T-shirts visually appealing. |

| Material Versatility | DTF transfers adhere to various materials, including cotton and polyester, allowing for greater creativity than traditional methods. |

| Cost-Effectiveness | Lower setup costs and no minimum order requirements make DTF an ideal option for small to medium businesses. |

| Ease of Use | The DTF process is user-friendly, involving design creation, film printing, and heat transfer, suitable for beginners. |

| Environmental Considerations | Using water-based inks, DTF transfers are more eco-friendly than many solvent-based inks, appealing to conscious consumers. |

| Recent Developments | Key advancements include better ink quality and increased production speeds, enhancing printing efficiency. |

| Market Trends | The DTF market is growing as more platforms adopt this technology, leading to a shift towards personalized fashion. |

| Getting Started | Invest in quality equipment, learn graphic design software, experiment with designs, and focus on marketing strategies. |

Summary

DTF transfers are indeed revolutionizing the T-shirt printing industry with their remarkable quality and adaptability. Embracing this innovative technology allows businesses and creators to produce vibrant, detailed designs on various materials while minimizing costs and maximizing efficiency. As more companies recognize the advantages of DTF technology, its market presence is expected to continue growing, solidifying its importance in the custom apparel landscape. With DTF transfers, the future of T-shirt printing is bright, offering exciting opportunities for creativity and business success.