In the dynamic realm of custom apparel printing, DTF transfers, or Direct to Film transfers, have rapidly gained recognition for their innovative approach. This technique offers a unique way to produce vibrant and durable designs on various fabrics, making it an essential tool for anyone in the design and printing industry. As individuals and businesses seek efficient and cost-effective methods for custom apparel, understanding the benefits of DTF transfers becomes crucial. From unparalleled color quality to compatibility with multiple materials, this printing method is transforming the landscape of textile customization. In this article, we will delve deeper into the various applications and techniques of DTF transfers, ensuring you have all the insights needed for success.

When it comes to cutting-edge textile printing, the term Direct to Film (DTF) might be the buzzword everyone is talking about. This revolutionary method allows for high-resolution imagery to be transferred seamlessly onto fabrics, paving the way for custom designs that truly stand out. Known for its versatility, DTF printing techniques cater to a myriad of applications, from sportswear to promotional merchandise. Exploring the numerous benefits of DTF transfers reveals how this technology is reshaping the industry, offering both creators and consumers lasting quality and captivating visuals. Join us as we unveil the intricacies of this adaptable method that’s captivating hobbyists and entrepreneurs alike.

Understanding DTF Transfers: A Comprehensive Overview

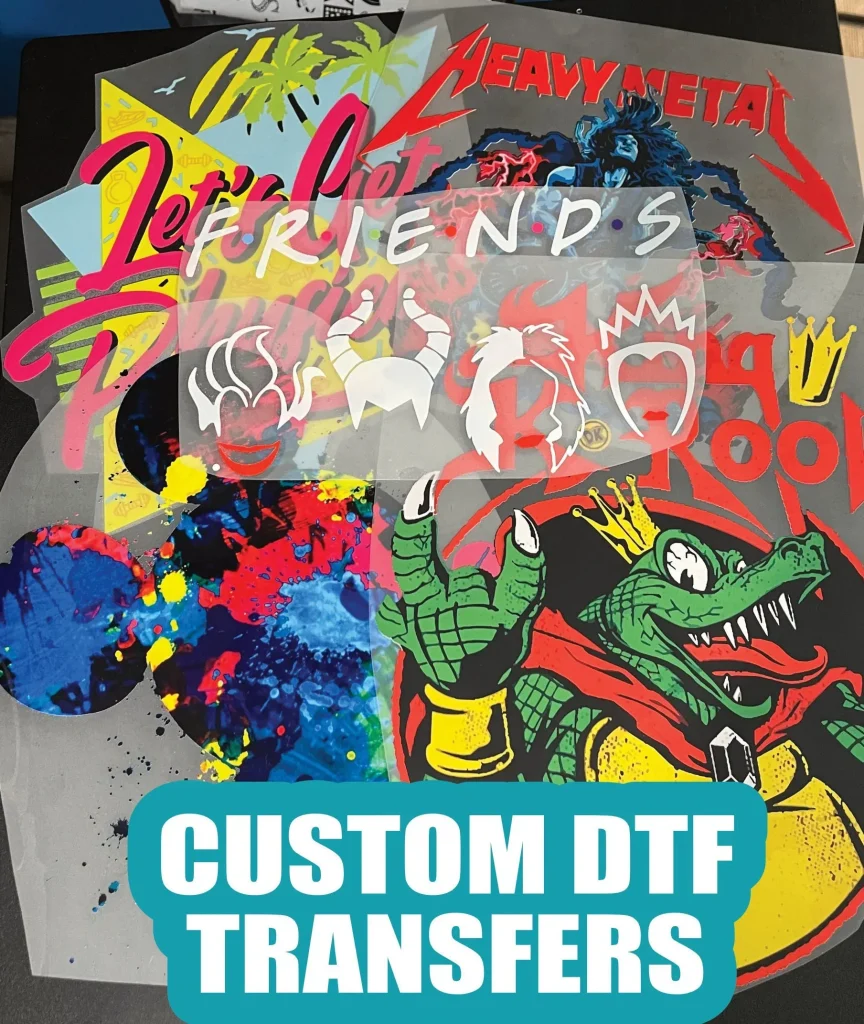

DTF (Direct to Film) transfers represent a significant leap in modern printing technology, especially within the custom apparel sector. This innovative process begins with designs that are printed onto a specialized film using high-quality water-based inks. Once the design is imprinted, the film is heat-pressed onto fabric, allowing a vibrant transfer of the artwork. Unlike traditional screen printing methods, DTF transfers provide greater adaptability across various materials, ensuring that intricate designs and vivid colors can be achieved on almost any fabric type.

The appeal of DTF transfers lies not only in their innovative printing technique but also in their versatility. Whether you’re designing t-shirts, tote bags, or other custom apparel, DTF transfers can be utilized on diverse fabrics, including cotton, polyester, and even more challenging surfaces like nylon and leather. This flexibility opens up avenues for designers to create personalized items that cater to a variety of customer preferences, showcasing their artistic capabilities while delivering top-notch products.

Exploring the Many Benefits of DTF Transfers

One of the standout benefits of DTF transfers is their remarkable durability compared to traditional printing methods. DTF-printed designs resist fading and cracking, even after multiple washes, making them perfect for high-use items such as sportswear and work uniforms. The longevity of DTF prints means that businesses can provide customers with high-quality products that stand the test of time, enhancing customer satisfaction and repeat business.

Furthermore, the cost-effectiveness of DTF transfers cannot be overstated. For small businesses and independent creators, the ability to print smaller batches without incurring high setup costs is a game changer. DTF technology allows for economical production of custom items, which is particularly advantageous for personalized orders. This economic viability ensures that even startups can thrive in the competitive landscape of custom apparel printing.

Techniques for Achieving Optimal DTF Transfers

To achieve top-quality DTF transfers, investing in high-quality materials is paramount. Using premium DTF films and inks will directly impact the vibrancy and adhesion of the designs on fabric. Quality materials not only ensure better transfer results but also enhance the overall longevity of the printed items, which is essential for maintaining a reputation in the custom printing market.

In addition to high-quality materials, proper preparation of the fabric before applying DTF transfers is a necessary step. By pre-pressing the fabric, one can eliminate moisture and wrinkles, leading to improved adhesion during the transfer process. This preparation is crucial for achieving a professional finish and maximizing the effectiveness of DTF printing techniques.

DTF Transfer Applications Across Various Industries

The versatility of DTF transfers extends beyond just clothing; they are gaining traction in various industries for a multitude of applications. In addition to custom apparel like t-shirts and hoodies, DTF transfers are increasingly used for promotional items, enabling businesses to customize everything from uniforms to promotional giveaways. This adaptability makes DTF transfers an excellent choice for branding efforts, effectively enhancing visibility and engagement with target audiences.

Moreover, DTF transfers have found a niche in home décor and crafting projects. Hobbyists utilize this innovative printing technique to create customized home goods such as cushions, wall art, and tablecloths. As interest in DIY projects continues to grow, the application of DTF technology supports individual creativity and personal expression, catering to a burgeoning market aimed at personalized home experiences.

Innovative Trends in DTF Printing Technologies

The popularity of DTF transfers is on the rise, with trends indicating a surge in demand for personalized and custom-made apparel. As consumers increasingly seek unique items that reflect their individuality, DTF transfers have emerged as a go-to solution for small businesses and crafters alike. This heightened demand is not just a fleeting trend; it represents a shift towards customization in the fashion and promotional product industries.

Moreover, advancements in DTF printing technology are making the process more accessible and efficient than ever. With improved printer designs and faster production methods, both novice and experienced users can employ DTF transfers with ease. These continual improvements in technology encourage more creators to explore the possibilities of DTF printing, further enhancing the industry landscape.

Final Thoughts on DTF Transfers in Custom Printing

As DTF transfers continue to revolutionize the landscape of custom printing, they provide creators with an array of possibilities for expression. Whether engaging in business or personal projects, understanding the technology and its application can greatly enhance the creative journey. Embracing DTF transfers means appreciating not just the process, but the artistic opportunities they present for individual and business branding.

In conclusion, as the market for personalized apparel and goods expands, the integration of DTF transfers within this segment is likely to grow. Those who leverage the benefits of DTF technology, from its intricate designs to its cost-effective production capabilities, will find themselves well-positioned to thrive in the dynamic world of custom printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern custom apparel printing technique where designs are printed onto a special film using a DTF printer. The printed film is then applied to fabric with heat and pressure, producing vibrant and detailed designs that adhere well to various materials.

What are the benefits of DTF transfers compared to other printing methods?

The benefits of DTF transfers include high durability, exceptional color vibrancy, and versatility across different fabric types. Unlike traditional heat transfers or screen printing, DTF transfers can produce intricate designs and are more cost-effective for small batches, making them ideal for custom apparel printing.

What materials can be used with DTF transfer techniques?

DTF transfers are adaptable to a wide range of fabrics, including cotton, polyester, nylon, and even leather. This versatility allows for the creation of custom apparel across diverse materials, making DTF printing applications suitable for various projects.

How can I ensure a successful application of DTF transfers?

To ensure successful DTF transfer applications, invest in quality DTF films and inks, properly prepare the fabric by pre-pressing it, and carefully adjust heat and pressure settings according to the fabric type. Additionally, allow sufficient curing time after application for optimal adhesion.

What are some common applications for DTF transfers in custom printing?

Common applications for DTF transfers include custom t-shirts, hoodies, promotional merchandise like hats and bags, home decor items such as cushions and tablecloths, and unique craft projects. This wide range of uses makes DTF transfers an appealing option for both businesses and hobbyists.

Are there any trends influencing the growth of DTF transfers in the printing industry?

Yes, there are rising trends influencing DTF transfers, including increased demand for personalized apparel and advancements in printing technology. These innovations make DTF transfers more accessible and efficient, attracting small businesses and crafters to this versatile printing method.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed on a special film and heat pressed on fabrics. |

| Benefits of DTF Transfers | Versatility, durability, detail, vibrant colors, and cost-effectiveness. |

| Techniques for Success | Invest in quality materials, prepare fabrics properly, use correct heat and pressure settings, and properly cure the transfers. |

| Uses of DTF Transfers | Apparel, promotional items, home décor, and craft projects. |

| Current Trends | Rising popularity and technological advances in the DTF printing process. |

Summary

DTF transfers are a groundbreaking method in custom apparel printing that combines quality and versatility. This innovative technology allows for high-definition designs to be printed onto various fabrics using a unique transfer process. As the demand for DTF transfers increases, stakeholders from hobbyists to commercial enterprises are finding new ways to utilize this technique. By focusing on essential elements such as material quality and proper transfer methods, users can achieve vibrant, durable prints that stand out. The increasing popularity and advancements in DTF printing technology indicate a bright future for this printing method, solidifying its role as a game changer in the industry.