In the fast-paced world of printing, especially with the rise of Direct-to-Film (DTF) printing technology, the DTF Gangsheet Builder has emerged as an essential tool for maximizing print efficiency. This innovative resource enables businesses to streamline their print production processes by allowing multiple designs to be printed simultaneously on a single sheet, drastically reducing material waste. The gang sheet method enhances not only the efficiency but also the cost-effectiveness of any printing operation. As we delve deeper into how to effectively utilize a DTF gangsheet builder, it’s crucial to understand its benefits and the best practices that can lead to enhanced productivity. Join us as we explore the transformative impact of this technique on the realm of printing and how you too can maximize your output.

The DTF Gangsheet Builder, often referred to as a design layout tool for Direct-to-Film printing, plays a pivotal role in improving overall print productivity. This approach enables the efficient organization of multiple print designs onto a single sheet, optimizing material usage and reducing waste. As industry trends shift towards more sustainable practices, the gang sheet technique offers a way to meet customer demands without sacrificing quality. In today’s print production landscape, utilizing cutting-edge DTF printing technology can ensure that businesses remain competitive by enhancing both efficiency and scalability. Let’s take a closer look at how this innovative method can revolutionize your printing capabilities.

Understanding the Benefits of DTF Printing Technology

Direct-to-Film (DTF) printing technology has revolutionized the printing industry by providing a highly efficient means of transferring designs onto various fabric materials. One of the key benefits of DTF printing is its ability to produce vibrant and detailed prints that withstand the test of time, making it an ideal choice for custom apparel businesses. With the use of high-quality inks and advanced printing techniques, DTF printing has become synonymous with delivering striking visuals that appeal to consumers, whether for t-shirts, hoodies, or other garments.

In addition to high-quality output, DTF printing technology enhances print efficiency by enabling the simultaneous printing of multiple designs on a single film. This method reduces the amount of material used and cuts down on production time. Businesses utilizing a DTF gangsheet builder can leverage this capability to maximize their printer’s efficiency, decreasing operational costs while delivering more designs to the market quickly. As a result, DTF printing positions itself as a powerful player in the fast-paced world of custom printing.

Exploring the Role of Gang Sheets in Print Production

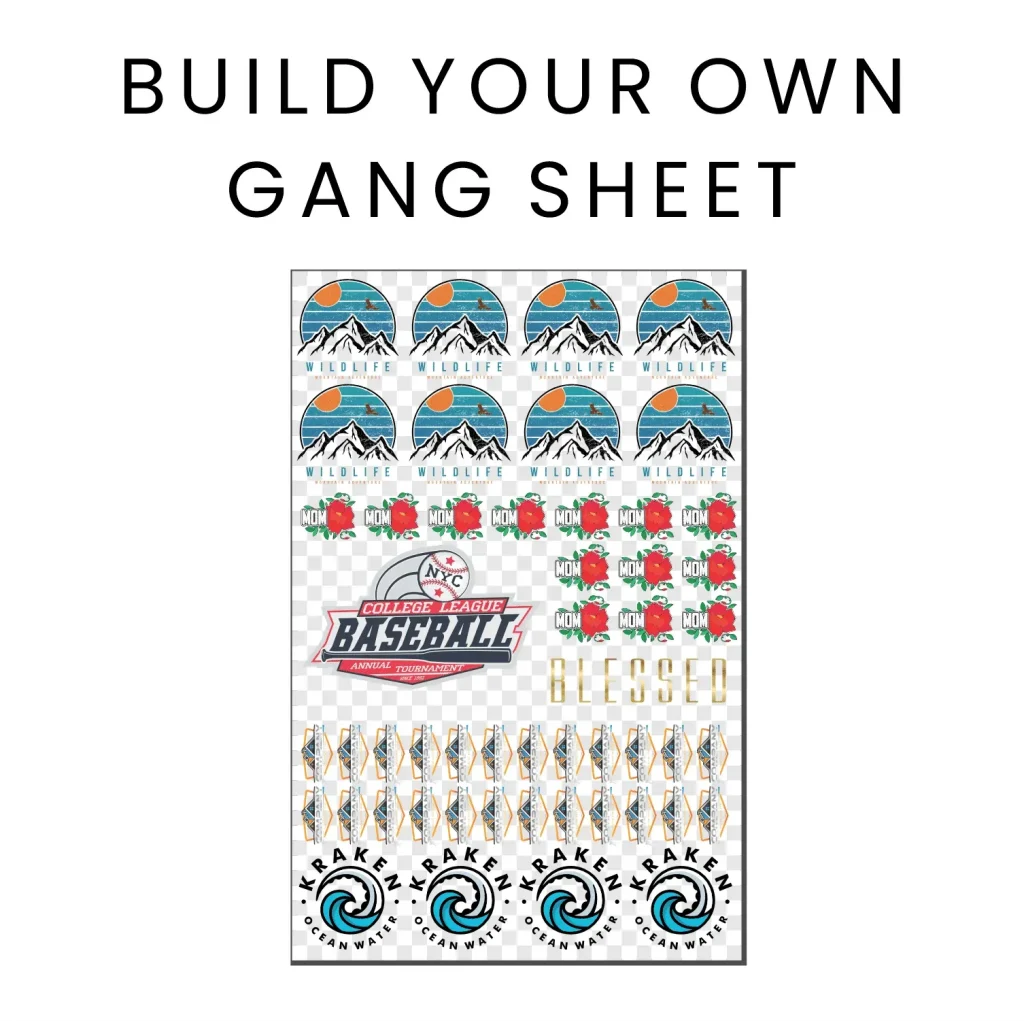

Gang sheets serve as a pivotal tool in print production, enabling manufacturers to print several designs on a single sheet simultaneously. This technique not only conserves resources by minimizing waste but also optimizes printer capacity, ensuring that every inch of the film is used effectively. When using a DTF gangsheet builder, print providers can create intricate layouts that maximize the number of designs per sheet, thereby increasing productivity and efficiency.

Moreover, gang sheets streamline the production workflow by simplifying the heat transfer process. With multiple designs printed on one sheet, businesses can eliminate the redundancy associated with printing individual transfers. The ability to transfer multiple designs at once can substantially reduce the time spent in production, allowing companies to fulfill larger orders more efficiently. Consequently, integrating gang sheets into DTF print production not only enhances operational efficiency but also fosters greater customer satisfaction through timely delivery.

Optimizing Layouts for Maximum Print Efficiency

Layout optimization is crucial when using a DTF gangsheet builder to enhance print efficiency. By thoughtfully arranging designs on a gang sheet, print providers can increase the number of designs printed per batch while minimizing waste. This thoughtful design approach should consider dimensions, spacing, and overall arrangement to ensure each design fits harmoniously within the sheet without unnecessary gaps.

Properly optimized layouts not only improve print efficiency but also contribute to the final appearance of the products. Designs aligned with precision on a gang sheet equate to cleaner transfers, reducing the likelihood of misalignment during application. By utilizing design software that specializes in gang sheet creation, users can easily visualize the arrangement and make necessary adjustments to ensure optimal layouts that maximize production capabilities.

Essential Design Software for DTF Printing

Investing in quality design software is integral to streamlining the gang sheet creation process within DTF printing. Specialized software tools provide features specifically designed for optimizing layouts, managing spacing, and allowing for easy adjustments. This software enables users to seamlessly combine multiple designs into one cohesive sheet with precision, enhancing both efficiency and print quality.

Additionally, many design software solutions come equipped with templates and guides that facilitate the gang sheet layout process. This user-friendly approach aids print providers, especially those new to DTF printing, by helping them avoid common pitfalls. An efficient design workflow ultimately translates to better printing outcomes, reinforcing the role of specialized software as a critical component in successful print production.

Monitoring Production for Continuous Improvement

Monitoring production performance is essential for businesses utilizing DTF gangsheet builders. By tracking metrics such as print speed, transfer quality, and waste levels, companies can identify areas needing improvement. This ongoing analysis enables printers to adjust their gang sheet layouts, optimize material usage, and enhance overall print efficiency.

Moreover, consistent monitoring encourages businesses to stay ahead of industry trends and innovations, allowing them to refine their processes continually. As new technologies emerge in the DTF printing landscape, understanding performance metrics can inform decisions about upgrading equipment or adopting new techniques, further elevating print production capabilities.

Staying Ahead with DTF Innovations

The DTF printing industry is rapidly evolving, with new innovations and technologies consistently emerging. Businesses that stay informed about these advancements can integrate cutting-edge solutions into their operations. For instance, advancements in ink formulations, heat transfer processes, and printing equipment can enhance the efficiency of DTF printing while improving product outcomes.

By attending industry events and workshops, print providers can gain insights into the latest technologies that could impact their use of DTF gangsheet builders. Staying ahead of innovations not only strengthens a business’s competitive edge but also fosters a culture of excellence, ensuring that print businesses are prepared to meet rising consumer demands with high-quality and efficient production processes.

Frequently Asked Questions

What are the benefits of using a DTF Gangsheet Builder for print efficiency?

The DTF Gangsheet Builder significantly enhances print efficiency by allowing multiple designs to be printed on a single sheet, which reduces material waste and maximizes printer usage. This method streamlines production processes and lowers costs associated with Direct-to-Film printing.

How does a DTF Gangsheet differ from traditional printing methods?

Unlike traditional printing methods where designs are printed individually, a DTF Gangsheet combines several designs onto one sheet. This approach not only minimizes waste but also optimizes print production, making Direct-to-Film printing more efficient.

What should I consider when optimizing my DTF Gangsheet layout?

When optimizing your DTF Gangsheet layout, focus on minimizing white space, ensuring proper spacing between designs, and considering the arrangement for easy application. This will help improve print efficiency and ensure clean transfers during Direct-to-Film printing.

Can design software improve the efficiency of my DTF printing process?

Yes, utilizing design software specifically for DTF Gangsheet creation can greatly improve printing efficiency. These tools allow for easy layout adjustments and provide guides that help visualize the arrangement of designs, enhancing overall print production.

How can I stay informed about the latest innovations in DTF printing technology?

Attending industry events like the DTF Expo and following relevant publications can keep you updated on the latest innovations in DTF printing technology, such as new heat press machines and production techniques that can enhance your use of a DTF Gangsheet Builder.

What is the key to developing effective gang sheets for my printing business?

To develop effective gang sheets, analyze the frequency of your designs, understand customer preferences, and optimize the layout according to production needs. Monitoring the performance of your gang sheets will also provide valuable insights for future improvements.

| Key Points | Description |

|---|---|

| What is a DTF Gangsheet? | A gang sheet prints multiple designs simultaneously, reducing waste and improving efficiency. |

| Understanding DTF Printing Technology | DTF printing transfers designs onto fabrics, known for its versatility and high-quality prints. |

| Recent Innovations in DTF Printing | Industry advancements like large-format printing from EazyDTF and new trade services from Snuggle are enhancing efficiency. |

| Practical Tips for Using a DTF Gangsheet Builder | 1. Optimize layout 2. Experiment with spacing 3. Utilize design software 4. Stay updated with innovations. |

| Developing a Gangsheet for Business Needs | 1. Review design frequency 2. Ensure design specificity 3. Monitor production for speed and quality. |

Summary

DTF Gangsheet Builder is a transformative tool in the printing industry, allowing businesses to maximize their print efficiency significantly. By enabling the simultaneous printing of multiple designs, this innovative approach minimizes waste, saves time, and streamlines production processes. The benefits of using a DTF Gangsheet Builder extend beyond cost reduction; they enhance the overall quality and speed of printing operations. To fully leverage this technology, businesses can optimize design layouts, maintain strategic spacing, and utilize specialized design software. Staying informed about the latest industry trends and innovations will further enhance the effectiveness of gang sheets. Embracing this method positions businesses at the forefront of the DTF printing market, fostering improved productivity and operational excellence.