The DTF Gangsheet Builder is a game-changer in the world of DTF printing, revolutionizing how designers approach textile printing by enabling the seamless arrangement of multiple designs on a single film sheet. As direct-to-film printing technology continues to gain traction, the importance of an efficient gangsheet builder cannot be overstated, as it directly impacts the quality, speed, and cost-effectiveness of your printing projects. This innovative tool consolidates designs, streamlining the digital transfer printing process while maximizing both material usage and creative potential. With a focus on effective graphic design software integration, the DTF Gangsheet Builder empowers users to unleash their creativity and produce vibrant, durable prints that resonate with their audience. Dive into this guide to explore how leveraging a DTF Gangsheet Builder can elevate your printing operations!

In the realm of textile printing, the use of a design consolidation tool, often referred to as a gangsheet builder, plays a crucial role in enhancing the efficiency of the production process. This type of digital transfer software allows users to effectively coordinate multiple graphics on a single piece of film, minimizing material waste and boosting productivity. As the popularity of DTF printing rises, mastering the art of gangsheet printing becomes essential for anyone looking to make a mark in this vibrant creative field. This guide will introduce you to the essentials of using a gangsheet creator, ensuring you unlock the full potential of your fabric prints. Prepare to delve into a world where graphic design meets innovative printing technology, allowing for stunning textile results.

Understanding Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing is a revolutionary technique in the world of textile printing, allowing for the creation of vibrant, durable designs on various fabric surfaces. This method involves printing images onto a specially coated film, which are then transferred onto fabrics using heat and pressure. Enthusiasts and professionals alike have embraced DTF printing due to its versatility, enabling the production of complex designs with incredible detail and color accuracy. With advancements in DTF technology, users can now achieve high-resolution prints that were previously unattainable with traditional methods, enhancing the overall graphic quality of finished products.

In contrast to other printing methods, DTF printing provides an advantage in terms of color vibrancy and durability. The use of high-quality inks ensures that prints not only look stunning but also withstand washing and everyday wear. Moreover, the ability to print on a wide range of fabrics—from cotton to synthetic blends—makes DTF printing a popular choice for custom apparel, promotional items, and textile applications in various industries. As DTF continues to evolve, the intricacies of the process, such as utilizing a DTF gangsheet builder, further enhance its effectiveness and appeal.

The Advantages of DTF Gangsheet Printing

Utilizing a DTF gangsheet builder can vastly enhance production efficiency for businesses in the textile industry. One of the significant advantages of gangsheet printing is cost-effectiveness; by printing multiple designs on one sheet of film, users can effectively reduce their consumption of materials like transfer film and ink. This not only lowers production costs but also minimizes waste, a key consideration for environmentally conscious businesses. By optimizing layout and design placement, operators can maximize output while adhering to budget constraints, resulting in a win-win scenario for print shops.

Additionally, DTF gangsheet printing saves valuable production time. With the capacity to process multiple designs simultaneously, businesses can streamline their workflows, reducing the time spent in setup and processing individual prints. This efficiency is particularly beneficial for large orders or custom runs, allowing operators to focus on quality control rather than repetitive tasks. The integration of technology in gangsheet builders facilitates a quicker setup, making it easier for users to arrange their designs accurately, further accelerating the printing process.

Preparing Your Designs for DTF Printing

Preparation is a crucial step in the DTF printing process, especially when utilizing a gangsheet builder. To ensure optimal results, designers should start by using graphic design software like Adobe Illustrator or CorelDRAW to create high-resolution images tailored for printing. It’s essential to design with the specific fabric in mind, considering factors such as fabric type and print size. Properly sized graphics not only enhance the final product’s appearance but also make the transfer process more efficient by reducing the need for adjustments during printing.

Moreover, alignment and spacing are key factors in the design phase. When preparing designs for a gangsheet, it’s important to leave adequate space between each image to facilitate cutting and prevent overlap. Most gangsheet builders will offer guidelines to help users maintain appropriate distances, ensuring that each design remains intact during the printing and transfer process. By investing time in proper design preparation, you can vastly improve the quality and effectiveness of your DTF prints.

Optimal Layout Strategies for Gangsheet Printing

Crafting a well-organized layout for your gangsheet is essential to maximizing material efficiency and ensuring quality output. When using a DTF gangsheet builder, implement strategies such as grouping similar designs together. This method not only simplifies cutting after printing but also allows for visual consistency across various items being produced. Utilize the gangsheet builder’s tools to visualize how your prints will be arranged, making any necessary adjustments before finalizing your layout.

Furthermore, consider the different items you’ll be printing on, such as shirts or tote bags, and adjust the sizes of your designs accordingly to ensure that each one fits perfectly. A thoughtful layout takes into account the dimensions of each design and the fabric it will be applied to, enhancing overall adhesion and appearance. By paying careful attention to layout within the gangsheet, you can optimize your production process and achieve superior results with minimal waste.

Leveraging Technology with DTF Gangsheet Builders

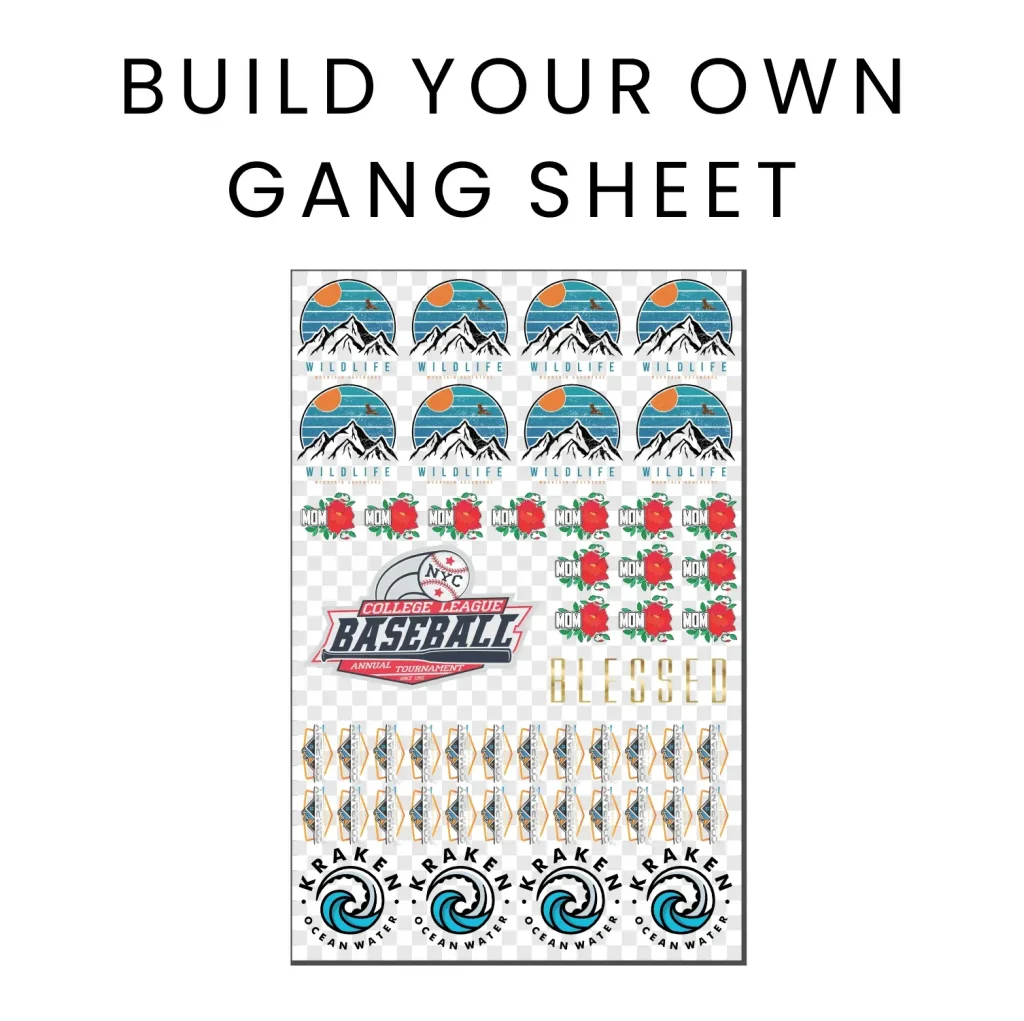

Modern DTF gangsheet builders are designed to streamline the printing process, making it accessible and efficient for users. Many platforms, such as Printful, offer intuitive interfaces that allow users to easily upload their designs and arrange them on a single sheet of film using drag-and-drop features. This technology not only saves time but also reduces the likelihood of errors that can occur with manual arrangements. The ease of use makes it possible for beginners and seasoned professionals alike to create high-quality gangsheet designs effortlessly.

Another notable feature of online gangsheet builders is the preview function, which allows users to see how their designs will look after printing before finalizing the layout. This invaluable tool helps in catching potential mistakes and ensuring that adjustments can be made on the fly, enhancing the overall quality of the prints. With these advanced features at your disposal, leveraging a DTF gangsheet builder is essential for achieving efficient and high-quality results in digital transfer printing.

Post-Printing Best Practices for DTF Transfers

After the printing process is complete, careful post-printing practices are vital to ensure the best results for your DTF transfers. Trimming each design from the gangsheet should be done meticulously to prevent any unwanted film from adhering to incorrect areas of the fabric. Proper trimming not only accommodates ease of application during heat transfer but also improves the overall aesthetics of the finished product, delivering professional results. Quality control at this stage prevents issues that could arise after the transfer has been applied.

Equally important is the curing process for your DTF prints. Following the recommended curing methods per the specific materials used ensures inks bind effectively to the fabric. This step is crucial for enhancing the durability and longevity of the prints, making sure they endure washing and wearing. Businesses that take these post-printing practices seriously will likely see better customer satisfaction, paving the way for repeat customers and positive word-of-mouth in the competitive textile printing market.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool used in DTF printing that allows users to arrange multiple designs on a single sheet of transfer film. This software typically includes features for drag-and-drop design placement, alignment guides, and previews to optimize the layout before printing. By maximizing space on the film, users can reduce material costs and waste associated with DTF printing.

How do I prepare my designs for the DTF Gangsheet Builder?

When preparing designs for the DTF Gangsheet Builder, it’s essential to use graphic design software such as Adobe Illustrator or Photoshop. Ensure your designs are high-resolution and appropriately sized for the intended materials. Proper alignment and spacing are crucial to avoid overlapping designs, facilitating easier cutting and application post-printing.

What are the benefits of using a DTF Gangsheet for digital transfer printing?

Using a DTF Gangsheet in digital transfer printing offers several advantages, including cost efficiency by printing multiple designs simultaneously, time savings due to reduced setup and processing times, and minimized waste from efficient design placement. This technique is vital for maximizing the benefits of DTF printing in textile design.

Can I use the DTF Gangsheet Builder for various fabric types?

Yes, the DTF Gangsheet Builder can be used for different fabric types. However, it’s important to adjust the design sizes according to the specific items you will be printing on, such as shirts, bags, or hats. This ensures proper adherence and quality in the final prints.

What should I consider when printing with a DTF Gangsheet?

When printing with a DTF Gangsheet, consider checking your printer settings to ensure they meet DTF printing specifications, including the right ink types, temperatures, and pressure levels. Additionally, using high-quality films is crucial for achieving vibrant and durable prints, enhancing the overall outcome of your DTF printing projects.

How can I ensure the quality of my prints after using the DTF Gangsheet Builder?

To ensure print quality after using the DTF Gangsheet Builder, carefully trim each design to prevent any excess material from affecting the application. Also, follow proper curing methods as per your DTF materials’ requirements to ensure that the inks adhere securely to the fabric, resulting in long-lasting and high-quality transfers.

| Key Aspect | Description |

|---|---|

| What is DTF Printing? | A printing method that transfers designs from a film to fabric using heat and pressure. |

| What is a Gangsheet? | A large film containing multiple designs for simultaneous printing, optimizing space and cost. |

| Benefits of Using DTF Gangsheet Builder | Cost efficiency, time-saving, and reduced waste through efficient design placement. |

| Preparing Your Designs | Use graphic software for high-resolution designs; ensure proper alignment and spacing to minimize waste. |

| Optimal Layout Considerations | Guidelines for spacing and adjusting sizes to fit different products. |

| Transport User-Friendly Features | Drag-and-drop assembly and preview functions in modern gangsheet builders. |

| Printing Considerations | Check printer settings and select quality films for best results. |

| Post-Printing Processes | Trimming designs accurately and ensuring proper curing after printing. |

| Sustainability | Minimizing waste through efficient use of DTF gangsheet enhances sustainable practices. |

Summary

DTF Gangsheet Builder is essential for anyone wanting to enhance their textile printing processes. With a profound understanding of DTF printing and the strategic use of a gangsheet builder, you can streamline your production, minimize waste, and achieve striking results. By focusing on preparation, layout, and leveraging modern tools effectively, your ability to create high-quality designs will flourish. Engage with additional resources and communities to further enrich your knowledge in the exciting realm of DTF printing.