DTF Application is at the forefront of innovation in the garment printing sector, providing an efficient alternative to traditional printing methods like screen printing. This technique allows for striking, high-quality prints on a variety of fabrics, catering to both small-scale and industrial needs. DTF printing utilizes unique DTF inks and transfer films to create vibrant designs that are both durable and cost-effective. As the popularity of heat transfer printing grows, mastering the DTF application process becomes essential for anyone looking to excel in the competitive world of garment printing. This guide will lead you through the nuances of DTF application, ensuring you achieve stunning results every time.

When discussing the innovative techniques within textile design, Direct-to-Film (DTF) transfer methods emerge as a game changer in the print industry. This technology empowers creators with the ability to produce vivid and long-lasting images directly onto various materials. Alternative methods, such as heat transfer printing, often fall short in comparison to the quality offered by DTF applications. By utilizing specialized inks and high-quality transfer films, artists and manufacturers can achieve results that are both aesthetically pleasing and robust. Embracing DTF technology not only enhances garment printing capabilities but also opens doors to creative possibilities previously thought unattainable.

Understanding DTF Printing Benefits

DTF printing is a game-changer in the world of garment printing, offering numerous benefits that make it a preferred method among creators and entrepreneurs alike. One of the main advantages is its ability to print on a wide range of fabrics, from cotton to polyester blends, without compromising on quality. The vibrant colors produced through DTF printing are unmatched, as the inks penetrate the fabric, providing a permanent finish that remains durable even after multiple washes. Moreover, DTF printing enables customization at a low cost, allowing small businesses and independent designers to produce small batches of unique apparel quickly and affordably.

In addition to versatility and color quality, DTF printing promotes efficiency in production. The process eliminates the need for screens or plates, which are essential in traditional silk screening methods. This not only speeds up the production cycle but also reduces material waste. With the advancements in DTF technology, like better inks and adhesive powders, the whole application process has become more streamlined, ensuring that prints are not only vivid but also long-lasting. As a result, the garment printing landscape is shifting, providing more opportunities for innovation and creativity.

Choosing DTF Transfer Materials Wisely

When it comes to DTF application, selecting the right transfer materials is crucial for achieving high-quality prints. High-quality DTF transfer films are essential as they directly influence how well the ink adheres to the fabric during the heat transfer process. It’s recommended to source films specifically designed for DTF printing, ensuring compatibility with both your printer and the adhesive powders. Poor-quality film can lead to issues such as smudging or incomplete transfers, which can affect the overall appearance and durability of the garment.

In addition to films, the selection of DTF inks plays a significant role in the printing outcome. DTF inks are formulated to deliver vibrant colors and are designed to bond effectively with both the film and fabric. It is advisable to choose inks that boast high washability and resistance to fading, as these qualities are essential for garments that will see regular use. By investing in top-notch transfer materials, one can enhance the quality of their prints, ensuring customer satisfaction and repeat business.

Essential Equipment for DTF Application

Investing in the right equipment is fundamental to mastering DTF application. At the heart of the setup is the DTF printer, which should be capable of delivering high-resolution prints that reflect the fine details of your designs. Popular brands such as Epson and Mimaki offer machinery tailored for DTF printing, featuring user-friendly interfaces and advanced technology that supports a variety of fabrics. Furthermore, it is crucial to match the printer specifications with the volume of production you anticipate, as this can greatly impact efficiency and output quality.

In addition to the printer, the heat press is another vital component in this process. Ensuring the heat press maintains consistent temperature and pressure is essential for successful transfer. A high-quality heat press allows you to adjust settings accurately, providing the versatility needed for different fabric types and ink formulations. Lastly, don’t overlook the importance of additional accessories like adhesive powders, which are necessary for effective bonding during the transfer process. The right equipment, when paired with diligent care and maintenance, will significantly elevate your DTF application results.

Design Preparation for Optimal Results

Preparing your design correctly is a key step in DTF application that directly impacts the final product. Using design software like Adobe Illustrator or CorelDRAW, you can create bold, eye-catching graphics that will translate well to fabric. It’s critical to set your resolution to at least 300 DPI to ensure sharp images, as low-resolution files can result in pixelation during printing. Moreover, considering the color profiles applicable to DTF printing can help achieve the desired vibrancy in the final output.

Another significant consideration in design preparation is simplicity; while intricate designs may be appealing, they often do not transfer well. Instead, focus on solid colors and bold lines, which will maintain clarity during the printing and transfer process. Testing designs on different fabrics can also be a valuable practice, allowing you to see how colors appear on various materials and make adjustments as needed. By carefully preparing your designs, you’re setting the stage for a successful DTF application that delights customers.

Executing the DTF Printing Process

Executing the DTF printing process requires precision and attention to detail to ensure that each print meets quality standards. Start by properly configuring your DTF printer settings, including nozzle height and media type, to achieve the best results. It’s also advisable to conduct test prints to calibrate colors and settings before processing bulk orders. Allowing the printed ink sufficient time to dry before applying adhesive powder is crucial; this can prevent smudging and ensure a clean transfer.

Once the design is printed and the ink has dried, evenly applying adhesive powder over the film is next. The amount and distribution of adhesive play a significant role in the transfer’s longevity and durability. After applying the adhesive, it is imperative to accurately heat press the design, ensuring consistent pressure and temperature based on fabric types. Following this process faithfully will dramatically improve the quality of your DTF prints, making them just as vibrant and durable as envisioned.

Heat Transfer Techniques for DTF Success

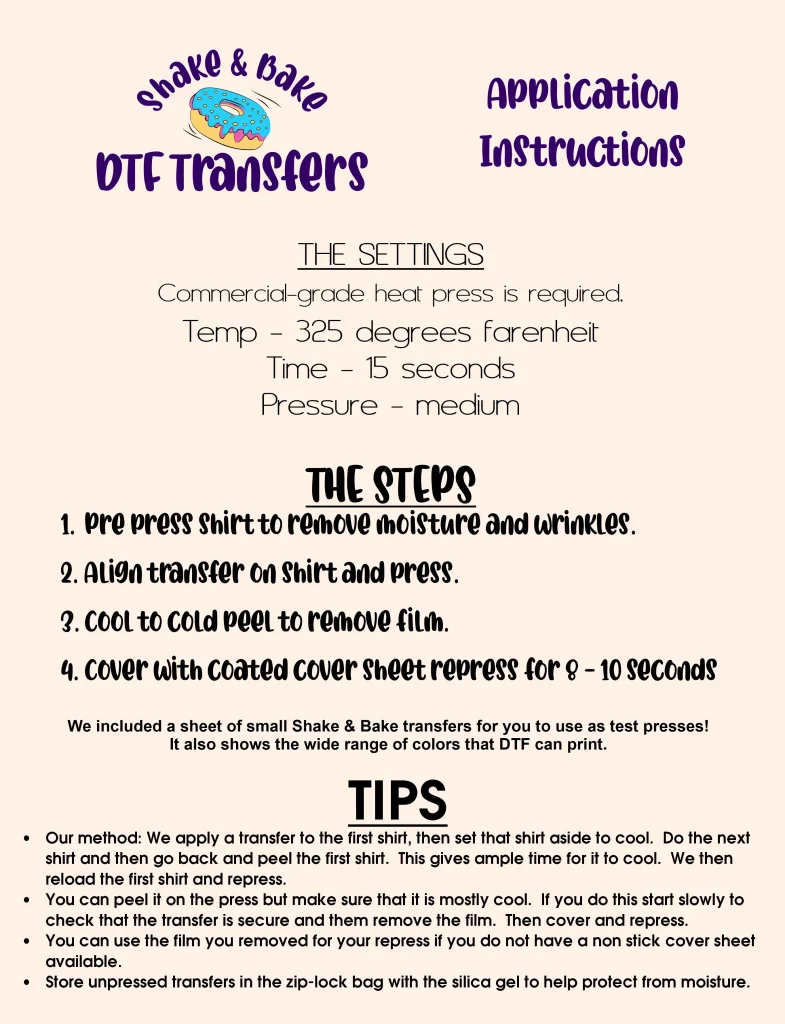

Successful heat transfer is one of the most critical stages in the DTF application process. To achieve the best outcome, preheating the heat press to the correct temperature—typically around 320°F (160°C)—is essential for activating the adhesive. Careful placement of the printed film on the fabric ensures optimal bonding, as misalignment can lead to incomplete transfers. Applying consistent pressure for the recommended duration—usually between 15-20 seconds—ensures that the design adheres fully to the garment during the transfer process.

After pressing, patience is key; allowing the transfer to cool slightly before peeling the film will help in achieving a smoother lift. A successful transfer is indicated by the design lifting cleanly from the film without leaving any adhesive behind on the fabric. If any part of the design has not adhered properly, this may necessitate reapplying heat or pressure to achieve the desired bond. Mastering these heat transfer techniques is fundamental for any DTF application and plays a vital role in delivering high-quality, durable garment prints.

Frequently Asked Questions

What is DTF Printing and how does it work?

DTF Printing, or Direct-to-Film printing, is a modern method of garment printing that involves printing designs onto a special film. This film is then transferred onto fabric using heat transfer techniques. The process typically includes printing with DTF Inks on the film, applying adhesive powder, and pressing it onto the garment, ensuring vibrant and durable results.

What equipment do I need for successful DTF Application?

To achieve a successful DTF Application, you need a reliable DTF printer, high-quality transfer film, DTF Inks, a heat press, and adhesive powder. Brands like Epson or Mimaki are recommended for printers, and the right type of film is crucial for compatibility with your printer, ensuring effective heat transfer printing.

How do I prepare a design for DTF Transfer?

Design preparation for DTF Transfer involves using graphic design software to create graphics with a resolution of at least 300 DPI. It’s important to keep designs simple and bold, as intricate details may not transfer successfully. Once designed, the artwork is printed onto the DTF film during the DTF Application.

What types of fabrics can I use DTF Printing on?

DTF Printing is versatile and can be used on a wide variety of fabrics including cotton, polyester, and blends. It is particularly effective on garments where vibrant color and durability are desired. This adaptability makes DTF Application suitable for diverse garment printing needs.

How long does the heat transfer take during the DTF Application process?

The heat transfer process in DTF Application typically takes about 15-20 seconds. It is important to set your heat press to the optimal temperature (usually around 320°F or 160°C) and apply consistent pressure to ensure a successful transfer of the design onto the fabric.

Are DTF Inks eco-friendly and safe for my business?

Many DTF Inks are now being developed with eco-friendly initiatives in mind. They are designed not only to provide vibrant results but also to lessen environmental impact. Choosing high-quality, sustainable DTF Inks can enhance your business’s reputation for using safer and greener printing practices.

| Key Steps | Description |

|---|---|

| 1. Choosing the Right Equipment | Select a reliable DTF printer and compatible transfer film to ensure high-quality prints. |

| 2. Ink Selection | Use DTF-specific inks that provide durability, bright colors, and adhere well to both film and fabric. |

| 3. Design Preparation | Create designs with high resolution and simple details using graphic design software. |

| 4. Printing Process | Print your design following precise settings to achieve quality results. |

| 5. Applying Adhesive Powder | Sprinkle adhesive powder over the printed film to ensure proper transfer. |

| 6. Heat Transfer | Use a heat press at the correct temperature and pressure to transfer your design. |

| 7. Peeling the Film | Remove the film carefully once cooled to check the transfer quality. |

| 8. Final Curing | Press with a protective sheet again to ensure durability and reduce peeling. |

Summary

DTF application is an innovative process that revolutionizes the garment printing industry by providing vibrant, high-quality prints. By mastering the steps outlined in this guide—from selecting the right equipment and inks to ensuring proper design preparation and final pressing—you will achieve not only visually stunning designs but also prints that stand the test of time. As the demand for DTF technology grows, understanding and implementing these practices positions you well in the competitive landscape of textile printing. Stay informed about recent technological advancements and sustainability practices to continuously refine your DTF application skills, ensuring your prints not only meet market demands but also resonate with the values of eco-conscious consumers.