In the ever-evolving world of garment production, the debate of DTF vs. DTG printing has become increasingly relevant for businesses aiming to optimize their textile printing methods. Both DTF (Direct to Film) and DTG (Direct to Garment) have distinct advantages and serve different purposes within the fabric printing techniques industry. As the demand for custom apparel grows, understanding the nuances between these two fabric printing techniques is essential for making informed decisions. This article dives deep into the comparison of DTF printing and DTG printing, highlighting their unique features and applications. By analyzing their strengths and weaknesses, we aim to help you determine which method truly reigns supreme in today’s vibrant market.

When exploring the realm of textile printing, two prominent methods often catch the attention of apparel manufacturers and designers: Direct to Film (DTF) and Direct to Garment (DTG). These innovative fabric printing techniques each offer a unique approach to transferring designs onto clothing, catering to a variety of production needs. DTF printing stands out for its ability to handle diverse fabric types efficiently, while DTG printing is favored for its capability to produce stunning detail in custom designs. As the landscape of fabric printing continues to transform, understanding the distinctions between these methods becomes crucial for anyone involved in the custom apparel industry. Join us as we delve into this comparison, providing insights to help you navigate the options available.

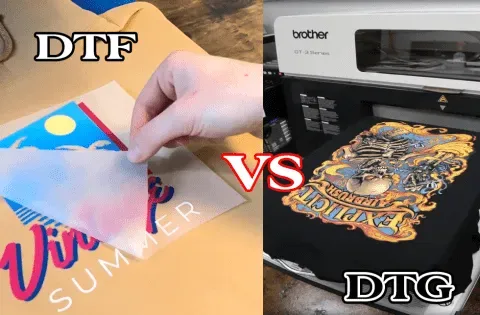

An Overview of DTF and DTG Printing

Direct to Film (DTF) and Direct to Garment (DTG) are two innovative textile printing methods that have redefined the custom apparel landscape. DTF printing involves creating designs on a special transfer film, which is then applied to the fabric using heat and pressure, allowing for a wide range of substrates to be printed on. In contrast, DTG printing applies ink directly onto the garment, akin to using an inkjet printer for paper, typically resulting in vibrant, high-definition imagery. Both methodologies cater to specific needs in terms of production volume, fabric type, and desired quality, influencing which technique may be deemed superior for a given project.

Understanding how these two processes differ is key for businesses aiming to produce high-quality garments efficiently. While DTF is versatile enough to handle various fabric compositions, including both light and dark materials, DTG shines when it comes to detailed images on cotton-based fabrics. This fundamental difference underpins many factors such as setup time, cost-effectiveness, and the scalability of production, which are critical considerations when selecting a suitable printing method.

Frequently Asked Questions

What is the main difference between DTF printing and DTG printing?

The primary difference between DTF (Direct to Film) and DTG (Direct to Garment) printing lies in the application and technology. DTF printing involves transferring designs from a film onto fabric using heat, making it versatile for various materials. In contrast, DTG printing applies ink directly onto the garment, best suited for high-detail designs on cotton fabric. Understanding this distinction is crucial when choosing between Direct to Film vs. Direct to Garment methods.

Which printing method, DTF or DTG, offers better durability?

DTF printing generally outperforms DTG printing in terms of durability. DTF prints are designed to resist cracking and fading, ensuring longevity even after repeated washes. While DTG prints offer high-quality visuals, they may not withstand wear as effectively as DTF outputs. Therefore, for items requiring robust durability, DTF printing is often the better choice.

Is DTF printing more cost-effective than DTG printing for large orders?

Yes, DTF printing is typically more cost-effective than DTG printing for large orders. DTF’s lower setup costs and ability to print efficiently on a variety of fabrics reduce expenses significantly when producing in bulk. DTG printing, while suitable for small runs and individual designs, tends to incur higher costs per unit, making DTF a preferred option for larger production volumes.

What types of fabrics can be used for DTF vs. DTG printing?

DTF printing offers great versatility as it can be used on a wide array of fabrics, including cotton, polyester, and blends. On the other hand, DTG printing is most effective on 100% cotton materials and often requires a pre-treatment process for dark garments. Thus, if you’re exploring fabric printing techniques across various fabric types, DTF may provide more options.

How does print quality compare between DTF and DTG methods?

When discussing DTF vs. DTG, print quality is a key consideration. DTG printing excels in producing vibrant and highly detailed images, making it ideal for intricate designs. However, DTF printing has improved significantly and offers good quality prints that are durable. For projects requiring exceptional detail, DTG might be preferred, but DTF provides a solid option for various applications.

What are the recent trends shaping the DTF and DTG printing industries?

Recent trends indicate a growing preference for DTF printing due to its adaptability and efficient production capabilities, especially for sustainable practices. Meanwhile, DTG continues to thrive in custom apparel markets due to technological advancements that enhance production speed and print quality. The choice between Direct to Film vs. Direct to Garment is influenced by these trends, as businesses seek the best fit for their unique needs.

| Key Factors | DTF Printing (Direct to Film) | DTG Printing (Direct to Garment) |

|---|---|---|

| Versatility | Can print on various fabrics including cotton and polyester, suitable for both light and dark garments. | Best suited for 100% cotton; requires pre-treatment for dark fabrics to ensure vibrancy. |

Summary

DTF vs. DTG are two prominent printing methods in the textile industry, each with its own strengths and applications. DTF printing offers remarkable versatility and durability, allowing for high-quality prints on a diverse range of fabrics, making it a favorite for businesses that require efficiency in large orders. On the other hand, DTG printing excels in producing intricate designs with high resolution, making it ideal for custom apparel, although it comes with higher per-unit costs for large batches. Ultimately, the choice between DTF and DTG depends on project requirements, including fabric type, production volume, and the desired print quality.