DTF transfers, also known as Direct-to-Film printing, have revolutionized the custom apparel landscape, providing an innovative solution for vibrant prints and durable designs. This cutting-edge printing technology allows businesses and designers to create stunning images on a wide array of fabrics, ensuring that every piece of clothing stands out. With unparalleled color depth and sharpness, DTF transfers are perfect for those looking to make a bold statement in their apparel lines. Furthermore, the cost-effective nature of this technique makes it accessible for small businesses and startups aspiring to leave a mark without incurring heavy expenses. Join us as we explore how DTF transfers can transform your printing process and boost your apparel offerings in today’s competitive market.

Referred to as Direct-to-Film (DTF) printing, this advanced technique has quickly ascended to popularity in the custom clothing sector. It represents a modern approach to textile printing that emphasizes high-quality, eye-catching designs perfect for various fabric types. This method is not only efficient but also caters to the diverse needs of designers and businesses looking to increase their product range. As a result, the market for apparel featuring vibrant, detailed prints continues to expand, accompanied by the advantages of quicker turnaround times and lower costs. By leveraging this innovative printing method, businesses can enhance their offerings and keep pace with ever-evolving consumer preferences.

Understanding the DTF Printing Process

Direct-to-Film (DTF) printing is a novel approach that has revolutionized textile printing by allowing designs to be printed directly onto a film. This process involves using specialized inks that are water-based, ensuring environmentally friendly printing options. The ability to create vibrant prints that withstand the test of time is one of the most appealing aspects of DTF printing. As designers create intricate designs, they can trust that the colors will remain sharp and vivid when transferred onto fabric.

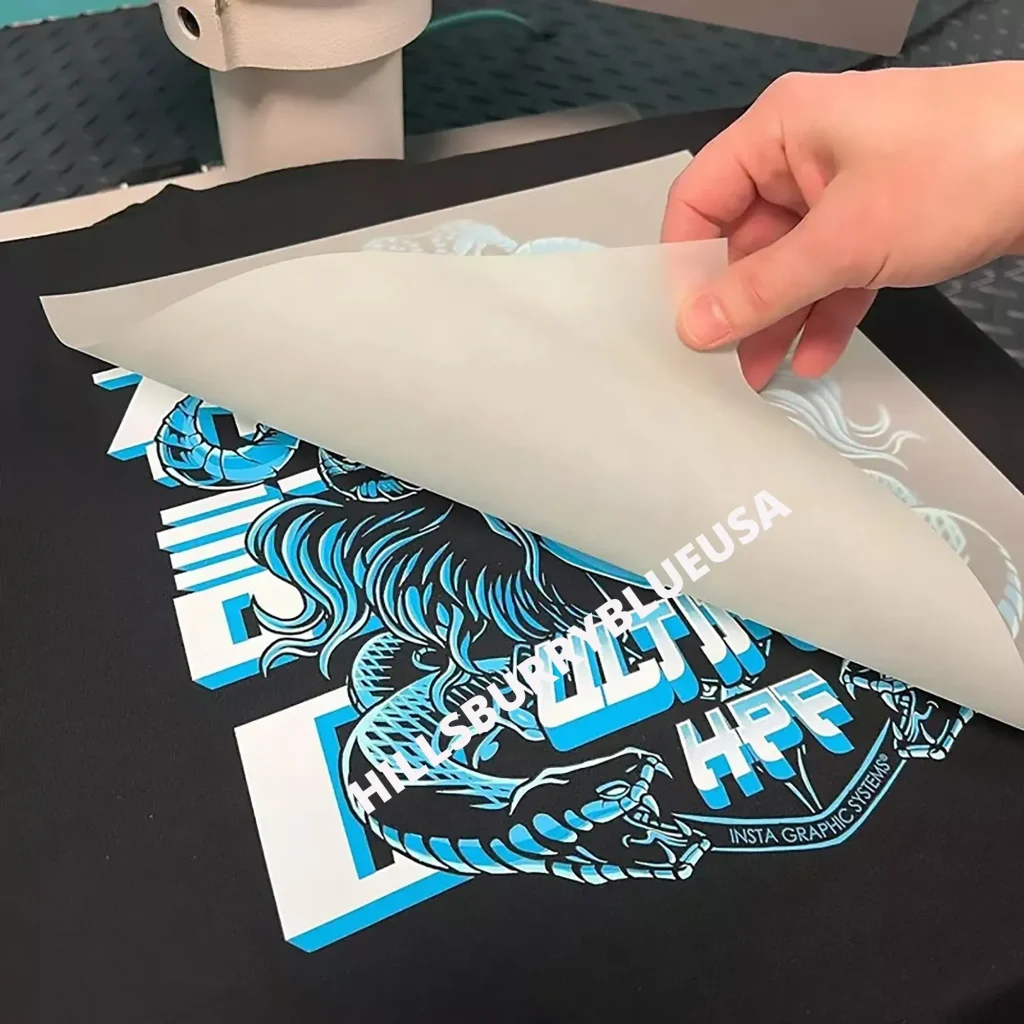

Additionally, the simplicity of the DTF process enhances its appeal in the custom apparel industry. After printing the design onto the film, a heat press is employed to transfer the image onto the chosen fabric. This quick and efficient method reduces production times significantly, making DTF an ideal choice for businesses that prioritize speedy order fulfillment without compromising on quality.

Overall, understanding the basics of DTF printing provides valuable insights for businesses looking to innovate in their printing techniques. As this technology becomes more widely adopted, it continues to shape the future of custom apparel in ways that align with contemporary consumer demands and preferences.

Durability of DTF Transfers: A Game-Changer in Apparel Printing

One of the key selling points of DTF transfers is their unmatched durability, which sets them apart from traditional printing techniques. Unlike methods that may result in designs fading or peeling after a few washes, DTF prints are engineered to endure the wear and tear of everyday use. This resilience is particularly beneficial for custom apparel that is frequently laundered, as it ensures that your vibrant prints remain intact and continue to represent your brand effectively.

Furthermore, the long-lasting quality of DTF transfers makes them a smart investment for businesses. With the ability to maintain their appearance through numerous cycles of washing, these transfers reduce the need for frequent reprints, ultimately saving time and resources for business owners. This advantage not only enhances customer satisfaction through high-quality products but also fosters brand loyalty as consumers receive apparel that looks as good as new for an extended period.

Vibrance and Color Quality in DTF Printing

The vibrancy of colors achieved through DTF transfers is truly remarkable, allowing designers to produce eye-catching graphics that stand out on various types of apparel. Utilizing advanced digital printing technology, DTF prints offer a depth of color that is unparalleled by many traditional methods. This characteristic is essential for brands that want their logos, artwork, or promotional materials to pop; it grabs attention and effectively communicates their message across different mediums.

Moreover, the ability of DTF transfers to maintain their color brilliance on dark fabrics is a significant advantage. While traditional printing methods often struggle with color saturation on darker materials, DTF technology thrives in this category. As a result, this opens up new creative avenues for designers and businesses alike, enabling them to expand their product offerings without limiting their choice of fabric types.

Cost-Effectiveness of DTF Transfers for Businesses

The growing popularity of DTF transfers has made them a cost-effective option for businesses venturing into custom apparel printing. Compared to traditional techniques like screen printing, which necessitates hefty setup costs and larger minimum order quantities, DTF printing allows for smaller batch sizes and on-demand production. This flexibility is particularly advantageous for startups and small businesses looking to minimize overhead while still delivering high-quality apparel.

Additionally, as advancements in DTF technology continue to emerge, competition has driven prices down, making it increasingly more accessible for all types of businesses. By leveraging cost-effective DTF transfers, companies can create diverse product lines without the risk of excess inventory and can cater to niche markets with ease. This model fosters a more sustainable approach, allowing entrepreneurs to thrive in a competitive landscape.

Exploring the Versatility of DTF Transfers

The versatility of DTF transfers is one of the key factors contributing to their rise in popularity among custom apparel providers. Unlike other printing methods that may be limited to specific fabric types, DTF technology can be used on a wide variety of materials. This includes cotton, polyester blends, leather, and more, presenting endless possibilities for creative expression. Designers can now exercise their creativity freely without the constraints that other methods impose.

This adaptability also allows businesses to diversify their product offerings confidently. Whether it’s creating custom t-shirts for an event, stylish hoodies for a clothing line, or even personalized bags, DTF transfers offer the flexibility to meet diverse customer demands. This ability to cater to different fabrics and styles not only enhances a brand’s marketplace presence but also elevates customer satisfaction by providing high-quality, customized products.

Navigating Recent Developments in DTF Technology

As the DTF printing industry evolves, staying informed about recent developments is crucial for businesses that want to maintain a competitive edge. Innovations such as improved heat transfer techniques and advancements in ink formulations have enhanced both the quality and efficiency of DTF transfers. Keeping up with these industry trends enables businesses to upgrade their equipment and practices for optimal results.

Additionally, companies that focus on in-house creation of DTF products will find themselves better positioned to respond to market demand. Firms like Sam’s DTF Transfers have prioritized this approach, allowing them to cater to their customers’ needs with speed and precision. By investing in research and development, businesses can leverage these technological advancements to create better products that meet evolving consumer preferences.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a specialized film with water-based inks. This film is then transferred onto fabric using heat and pressure, resulting in vibrant and high-quality prints suitable for custom apparel.

What makes DTF transfers a cost-effective printing solution?

DTF transfers are a cost-effective printing technology because they allow for on-demand printing and do not require expensive setup fees associated with traditional screen printing methods. This makes them ideal for small businesses looking to produce custom apparel without significant upfront costs.

Can DTF transfers be used on dark fabrics?

Yes, DTF transfers are known for their ability to produce vibrant prints even on dark fabrics. The technology ensures rich color depth and sharp designs, making it an excellent choice for apparel that needs to stand out.

What are the advantages of using DTF transfers over other printing methods?

DTF transfers offer unmatched versatility across various materials, including cotton and polyester blends, and provide exceptional durability against fading and cracking. These advantages, alongside simplified processes for quick turnaround, make DTF a superior choice compared to other printing methods like sublimation.

What types of custom apparel can I create with DTF transfers?

With DTF transfers, you can create a wide array of custom apparel including t-shirts, hoodies, tote bags, and hats. The versatility of this printing technology allows designers to cater to diverse customer needs across multiple types of fabrics.

How do DTF transfers ensure high-quality prints?

DTF transfers utilize advanced printing technology that enables sharp color reproduction and exceptional detail, resulting in high-quality prints that are durable and vibrant. This technology helps preserve the colors and sharpness of designs even after multiple washes.

| Key Points | Description | Advantages | |

|---|---|---|---|

| What are DTF Transfers? | Technology for printing designs on a special film and transferring them to fabric. | ||

| 1. Unmatched Durability | Resistant to fading and cracking, ensuring long-lasting prints even after washes. | ||

| 2. Vibrant and Sharp Coloration | Allows for high color depth and clarity, especially on dark fabrics. | ||

| 3. Cost-Effectiveness | Lower setup costs compared to screen printing, ideal for small orders and startups. | ||

| 4. Versatility Across Materials | Applicable to various materials like polyester, leather, and more for diverse products. | ||

| 5. Simplified Process and Quick Turnaround | User-friendly process that allows for fast and efficient production. | ||

Summary

DTF transfers are a revolutionary printing technology transforming the custom apparel industry with exceptional durability, vibrant prints, and cost-effectiveness. As more businesses embrace DTF transfers, it’s clear that they provide a competitive edge by allowing high-quality designs to be produced quickly and on various materials. This adaptability not only supports creative freedom but also aligns with market trends of customization and rapid production. For anyone involved in custom printing, leveraging DTF transfers is key to enhancing product offerings and meeting increasing consumer demands.