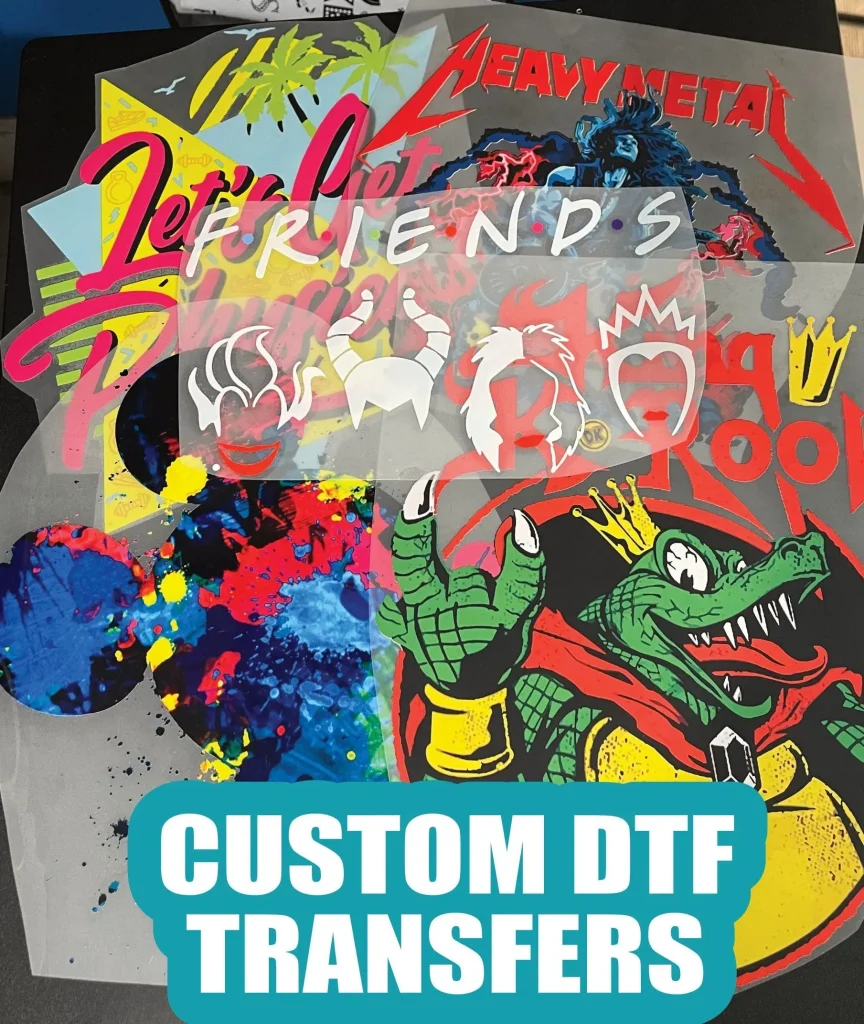

DTF transfers, or Direct-to-Film transfers, are revolutionizing the way we approach custom merchandise in today’s market. This innovative printing technique lays vibrant designs directly onto various materials, including apparel, bags, and home decor, making it a versatile choice for personalization. With the rising demand for sustainable printing solutions, DTF printing stands out as an eco-friendly alternative, significantly reducing waste compared to traditional methods. Additionally, this print-on-demand technology caters to both businesses and DIY enthusiasts, allowing anyone to create personalized apparel with ease. By integrating DTF transfers into your production process, you can elevate your merchandise offerings and resonate with eco-conscious consumers.

Direct-to-Film transfers are the latest trend in fabric customization, providing an efficient way to apply intricate designs to a multitude of items. This method, which blends innovation with sustainability, allows for the creation of custom merchandise such as apparel and accessories, while aligning with environmentally-friendly practices. The ease of use associated with this printing process makes it suitable for both small businesses and individual creators eager to explore personalized merchandise solutions. By utilizing DTF technology, you can open up new avenues for creative potential, ensuring your custom products stand out in an increasingly competitive market. This evolution in printing caters to a diverse array of materials and design possibilities, making it an ideal choice for today’s customization needs.

Understanding the DTF Printing Process

DTF printing, or Direct-to-Film printing, is revolutionizing the way custom merchandise is created. This innovative method involves printing a design onto a special film, which is then transferred onto the fabric, allowing for vibrant and intricate designs. The process ensures that the ink adheres better to the material, resulting in prints that are not only striking but also durable. Unlike traditional methods that require complex setups and materials, DTF printing offers a more efficient pathway to create personalized apparel.

The DTF printing process is straightforward, making it ideal for both beginners and seasoned professionals. It starts with designing your graphics, followed by printing the design onto a transfer film using specific DTF inks. Once printed, the film is then heated to transfer the design onto the chosen garment, ensuring strong adhesion and vivid colors. This accessibility has opened up the market to a wider audience, enhancing the overall appeal of custom merchandise.

Sustainability in DTF Transfers

Sustainability is becoming an integral aspect of product development, and DTF transfers are leading the charge in eco-friendly printing practices. Traditional printing methods often rely on harmful chemicals and generate excess waste, but DTF technology reduces these environmental impacts significantly. The process involves less water usage and fewer toxic byproducts, making it a greener choice for companies looking to enhance their sustainable practices. As consumers become more environmentally conscious, the demand for sustainable printing options is on the rise.

By choosing DTF transfers, businesses not only contribute to a healthier planet but also align with the values of today’s discerning consumers. This shift towards sustainability in the fashion and merchandise industry is reflected in the growing popularity of eco-friendly brands, which are now leveraging DTF printing to offer high-quality products with lower environmental footprints. The future of custom merchandise lies in this balance of creativity and responsibility, showcasing how DTF transfers can satisfy both aesthetic and ethical standards.

Innovative Applications of DTF Transfers

The versatility of DTF transfers allows for a wide range of applications beyond just clothing. From custom tote bags and hats to unique home decor items, DTF printing can be adapted for various materials and products. The ability to print on different fabrics expands the creative horizons for designers and allows businesses to cater to diverse customer needs. This adaptability is a significant advantage in the print-on-demand market, where consumer preferences are continually evolving.

Furthermore, DTF technology enables detailed and colorful designs without the limitation of specific fabric types. This means that small businesses and DIY enthusiasts can explore customization options that suit any occasion or personal style. As the market for personalized merchandise grows, DTF transfers stand out as a tool that empowers creators to push the boundaries of traditional product offerings.

DTF Transfers vs. Traditional Printing Methods

When comparing DTF transfers to traditional printing methods such as screen printing or heat transfer vinyl, several distinct advantages emerge. DTF technology allows for high-quality prints with greater detail and color vibrancy, making it the preferred choice for intricate designs. Additionally, DTF printing requires fewer setup costs and can handle low-volume orders efficiently, which is crucial for entrepreneurs looking to offer customized products without hefty upfront investments.

Moreover, while traditional methods often require specific materials, DTF transfers provide the flexibility to print on a wider variety of fabrics, including difficult-to-print surfaces like leather and blends of cotton. This broad range of applicability makes DTF printing ideal for promotional items, fashion apparel, and beyond, allowing brands to offer diverse and engaging products to their customers.

Ease of Use in DTF Printing

One of the standout features of DTF transfers is their user-friendly application process. For those new to custom printing, the DTF technique provides a simplified approach that alleviates common challenges associated with traditional methods. Resources and guides available online break down the steps involved, making it accessible even for beginners without extensive experience in graphic production or printing.

This ease of use extends to the equipment needed as well. With the right DTF printer and heat press in hand, users can quickly learn the ropes and begin producing customized merchandise. As a result, more creative individuals can dive into the world of personalized apparel, effectively expanding the reach of small businesses and offering products that resonate with their target audience.

Best Practices for Successful DTF Customization

Achieving the best results with DTF transfers requires adherence to certain best practices. Firstly, investing in quality DTF transfers is crucial; poorly made transfers can lead to suboptimal prints that don’t last. Alongside this, understanding the specific requirements of different fabrics, including whether pre-treatment is necessary, can greatly influence the outcome. By following detailed guidelines, users can enhance both the vibrancy and durability of their final products.

Another aspect to consider is the importance of using compatible equipment. Selecting the right DTF printer and ensuring proper temperatures during the transfer process can make a significant difference in achieving professional-looking results. Continual learning and iteration are vital; as users familiarize themselves with the intricacies of DTF printing, they’ll be able to refine their techniques and improve the overall quality of their personalized merchandise.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are an innovative printing method used to customize garments and merchandise. The process involves printing designs onto a special film that is then applied directly to fabrics, allowing for vibrant colors and complex patterns. This printing technique ensures a high-quality finish, ideal for creating personalized apparel and custom merchandise.

What makes DTF Printing a sustainable option for merchandise customization?

DTF printing is considered a sustainable option due to its reduced waste and lower environmental impact compared to traditional printing methods. DTF technology uses fewer harmful chemicals and minimizes material usage, which supports eco-conscious brands and appeals to environmentally aware consumers in the custom merchandise market.

Can DTF Transfers be used on different materials?

Yes, DTF Transfers are highly versatile and can be applied to a variety of materials such as cotton, polyester, leather, and more. This flexibility allows creators to expand their offerings beyond apparel to include items like bags, hats, and home decor, making it an excellent choice for personalized merchandise.

What equipment is necessary for successful DTF Printing?

To successfully use DTF Transfers, you need a compatible DTF printer, a heat press, and high-quality transfer films. Having the right equipment ensures optimal results in your custom merchandise production, allowing for efficient and professional-grade applications.

How can beginners get started with DTF Transfers for custom merchandise?

Beginners can start with DTF Transfers by following online guides that offer step-by-step instructions on purchasing transfers and applying them correctly. Investing in a compact DTF printer designed for print-on-demand setups can also help newcomers easily access the world of personalized apparel and custom merchandise.

What are the advantages of using DTF technology for customized products?

DTF technology offers numerous advantages including ease of use, high-quality prints with vibrant colors, and the ability to work with various fabric types. Additionally, it supports sustainable printing practices, making it an attractive option for businesses and individuals looking to create eco-friendly, personalized merchandise.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers enable custom designs to be applied to various materials using a specialized printing technique, offering vibrant colors and intricate designs. |

| Sustainability Aspect | DTF printing contributes to eco-friendliness by reducing waste and avoiding harmful chemicals, appealing to eco-conscious consumers. |

| Innovations in the Market | New technology (like compact DTF printers) allows for efficient production of customized merchandise, improving accessibility for businesses and individuals. |

| Versatility Across Materials | DTF transfers can be applied to multiple materials, including cotton and leather, extending customization beyond clothing. |

| Ease of Use | Simple application steps and available online guides make DTF printing accessible for both beginners and experienced users. |

| Best Practices | Investing in quality transfers, pre-treating fabrics, and following reliable guides will enhance the effectiveness of DTF printing. |

Summary

DTF Transfers are revolutionizing the customization landscape, providing a perfect blend of sustainability, versatility, and ease of use. By embracing DTF Transfers, you can cater to a growing market that values environmental responsibility while still enjoying the freedom of creative expression. The advancements in DTF technology empower both small businesses and individual creators to produce stunning, personalized merchandise that not only meets market demand but also stands out for its quality and design. As you explore the world of DTF Transfers, remember that your options are vast, and this guide is just the beginning of your creative journey.